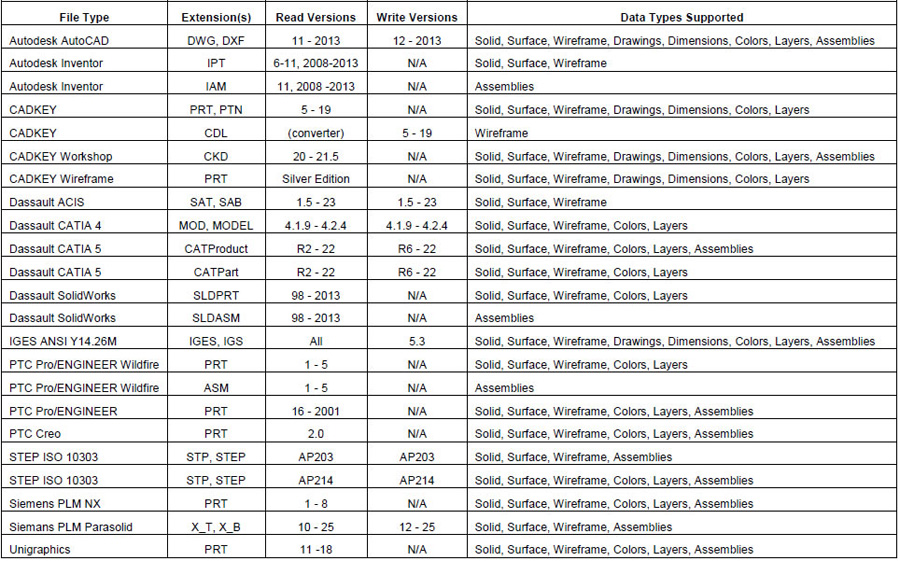

Tech Cast uses Kubotek's KeyCreator software for solid model design. KeyCreator can import customer supplied files or create models from scratch. Kubotek's overview displayed in KeyCreator_Datasheet.pdf provides further explanation of software capabilities. The translator table below provides conversion possibilities and file types accepted at Tech Cast.

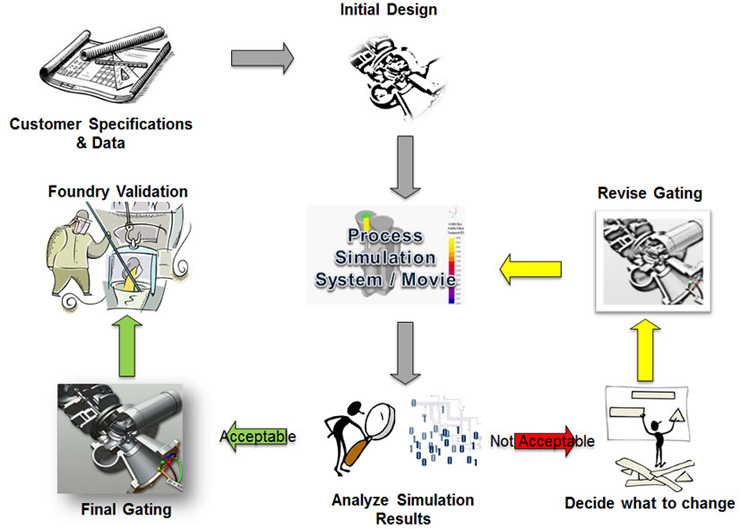

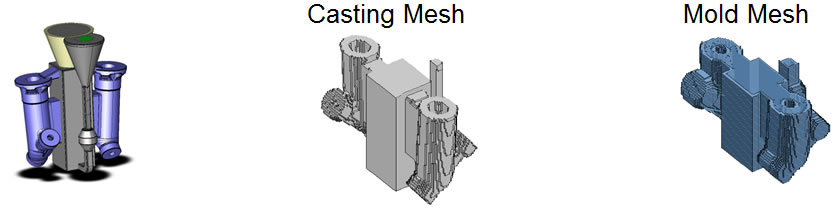

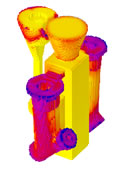

Tech Cast uses a solidification modeling package called SOLIDCast®, this software provides the foundry an early look into the solidification characteristics of any given gating system. The software allows Tech Cast engineers to identify possible problem areas of complex components before the investment casting tooling is designed and built. The software provides the needed flexibility during the initial investment casting design, and allows process parameters to be altered and tested without consuming valuable time. Solidification modeling helps Tech Cast to shorten lead times, reduce costs, and produce higher quality investment castings with improve yields.

SOLIDCast® lets you see how your casting will solidify before you make pattern equipment, dies and costly mistakes. Pour your test castings on the computer, not on the foundry floor! Design gates, risers and test them out before making your first casting. Solidification modeling helps you to shorten lead times, produce higher quality and improve yield. All of this means lower costs, higher profits and improved marketability for your foundry.

Parts with complex geometries and intricate details can be created with this process.

For R&D, part repairs, reverse engineers, low production quantities. Tech Cast can meet all of your SLA Rapid Prototype requirements.

Learn about how Tech Cast’s full range of capabilities can deliver the product that best meets your needs.