TRUSTED SPEED & PERFORMANCE

Challenge

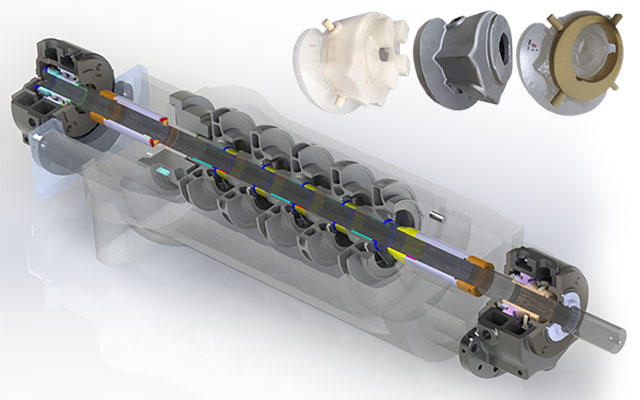

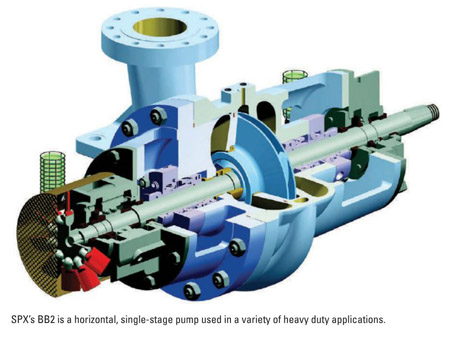

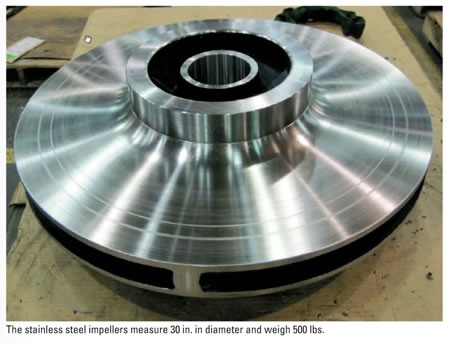

Sulzer Pumps needed a complex 300 lb casting, developed from concept to completion in 4 weeks.

Solution

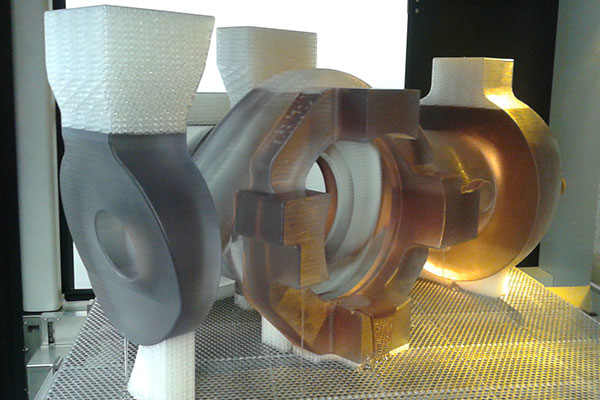

To produce a large, complex investment casting quickly, Tech Cast used additive manufacturing technology to expedite this critical casting. This solution saved time and money while producing a part with extraordinary dimensional accuracy.

Results

“Tech Cast’s execution of our highly critical order was beyond expectations. With a customer in dire need, their team rose to the occasion to meet our aggressive schedule without compromising quality. We appreciate the support provided by Tech Cast and will not hesitate to work with them in the future”

-Monica Sawatzky, Senior Buyer, Sulzer Pumps (Canada) Inc.

Why risk production downtime?

Specify the proven performance leader: Tech Cast.